What are vertical farms?

Generally, a vertical farm is a building that houses an entire agri-food chain: production, transformation, sale and human consumption. However, in most cases, vertical farms are defined as buildings that only accommodate production and transformation, which follow the principles of mass production lines: the aim of the structures, in fact, is to produce exact quantities of identical products in known time, and often these products are salads and aromatic herbs, which have much lower costs. To achieve this goal, the cultivation process takes place within a closed environment, completely controlled and independent from the external one, in which all environmental parameters are controlled. Soilless cultivation techniques, on the other hand, allow plants to be supplied with the exact amount of nutrients they need. In Italy, the sector is rapidly expanding and several interesting projects have been launched, and that aim to gain prominence at international level as well.

Future Farming District by Zero

Zero is a company from Pordenone that is planning a production plant called the Future Farming District, in Capriolo, in the centre of the Oglio Park, in Lombardy. An investment of 100 million euros for a hub capable of producing 1,300 tonnes of salads and herbs per year. The most innovative elements of Future Farming District are in the energy approach: the Capriolo plant, in fact, is in a former yarn mill in Capriolo equipped with hydroelectric power, undergoing redevelopment in collaboration with Iseo Idro - an investment company specialised in the acquisition and in the management of energy production plants from renewable sources - a move that allows great savings in terms of energy consumption and sustainability. Future Farming District will be an integrated circular ecosystem that is scalable and replicable in other contexts, which combines the local production of clean energy from renewable sources with vertical farm cultivation plants of flexible size and configuration.

In recent months, Zero has announced an agreement with Tamimi Markets Company and the Japanese multinational Mitsui to create a new joint venture for the development of smart vertical farms in Saudi Arabia. As for distribution, Zero manages its own line that will handle a small percentage of the products, for the rest a collaboration has been devised with Tramite, an intermediary company in the large-scale distribution sector, thanks to which Future Farming District will supply the products in private label for the main brands of large-scale distribution.

Future Farming District di Zero – Cariolo (Br) – zerofarms.it/

Planet Farms

Planet Farms is a project born on the outskirts of Milan that practices indoor agriculture with the support of cutting-edge technologies. In 2021 it built the largest vertical farming laboratory in Europe, surpassing the Taastrup lab in Copenhagen in a 9,000 square metre warehouse in Cavenago. The most evident advantage lies in the optimisation of resources, in an anti-waste function, with water savings that reach 90-95%, while the soil is not consumed and the growth parameters of the plants are controlled thanks to technology, without the use of pesticides. To tackle the path towards industrialisation and automation of cultivation operations in the Cavenago Brianza facility, Planet Farms made use of a collaboration with Siemens, which provided its technological innovations to support digital transformation along the entire production chain.

Planet Farms – Milan - planetfarms.ag/it

Agricola Moderna

Agricola Moderna is a Milan-based company that aims to grow vegetables with a low environmental impact through vertical farming, with plants that grow without soil and without sunlight. The project, initially started in via Col di Lana, within the Milano Food District, was transferred to Melzo in a production plant with an area of 1,500 square metres. The Agricola Moderna production method allows to cultivate without the use of pesticides, chemicals and with great attention to the environment, saving 95% of water and 98% of soil. The products are harvested daily, packaged within an hour of harvesting and delivered on the same day: this means a lot more freshness for the consumer, as well as a healthy, tasty and environmentally friendly product. The company mainly produces baby leafy vegetables harvested at a very young stage, throughout the year, maintaining a constant flavour thanks to light and nutrients, which it distributes with recycled and recyclable packaging throughout Lombardy.

Agricola Moderna – Milan – agricolamoderna.com

by Maurizio Gaddi

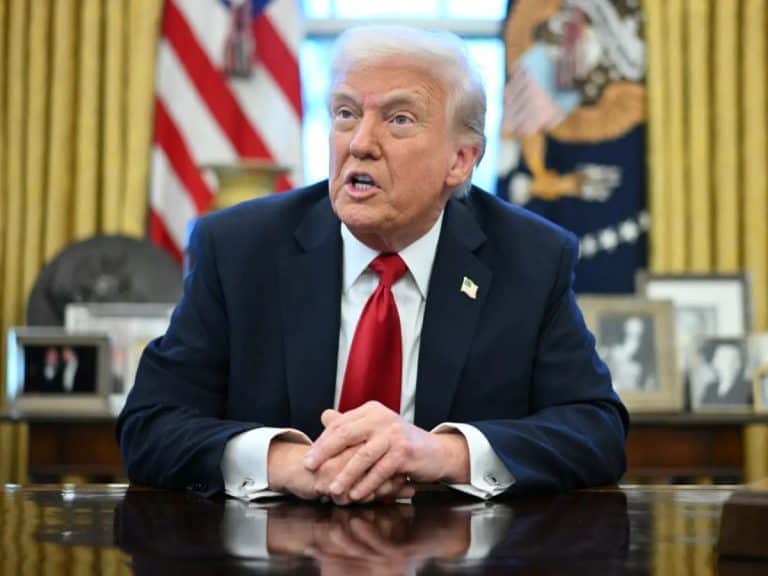

Farewell cacio e pepe in New York. "With tariffs, Pecorino Romano will also become more expensive." The warning from Giuseppe Di Martino

Farewell cacio e pepe in New York. "With tariffs, Pecorino Romano will also become more expensive." The warning from Giuseppe Di Martino Against tariffs? Here are the US foods that could be "hit"

Against tariffs? Here are the US foods that could be "hit" US tariffs: here are the Italian wines most at risk, from Pinot Grigio to Chianti Classico

US tariffs: here are the Italian wines most at risk, from Pinot Grigio to Chianti Classico "With U.S. tariffs, buffalo mozzarella will cost almost double. We're ruined." The outburst of an Italian chef in Miami

"With U.S. tariffs, buffalo mozzarella will cost almost double. We're ruined." The outburst of an Italian chef in Miami "With US tariffs, extremely high risk for Italian wine: strike deals with buyers immediately to absorb extra costs." UIV’s proposal

"With US tariffs, extremely high risk for Italian wine: strike deals with buyers immediately to absorb extra costs." UIV’s proposal